FACTORS AFFECTING STRENGTH OF CONCRETE

In general, concrete consists of coarse and fine aggregate, cement, water, and—in many cases— different types of admixtures. The materials are mixed together until a cement paste is developed, filling most of the voids in the aggregates and producing a uniform dense concrete. The plastic concrete is then placed in a mold and left to set, harden, and develop adequate strength. The strength of concrete depends upon many factors and may vary within wide limits with the same production method. The main factors that affect the strength of concrete are described next.

Water–Cement Ratio

The water–cement ratio is one of the most important factors affecting the strength of concrete. For complete hydration of a given amount of cement, a water-cement ratio (by weight) equal to 0.25 is needed. A water–cement ratio of about 0.35 or higher is needed for the concrete to be reasonably workable without additives. This ratio corresponds to 4 gal of water per sack of cement (94 lb) (or 17.8 lb per 50 kg of cement). Based on this cement ratio, a concrete strength of about 6000 psi may be achieved. A water–cement ratio of 0.5 and 0.7 may produce a concrete strength of about 5000 and 3000 psi, respectively.

Properties and Proportions of Concrete Constituents

Concrete is a mixture of cement, aggregate, and water. An increase in the cement content in the mix and the use of well-graded aggregate increase the strength of concrete. Special admixtures are usually added to the mix to produce the desired quality and strength of concrete.

Method of Mixing and Curing

The use of mechanical concrete mixers and the proper time of mixing both have favorable effects on strength of concrete. Also, the use of vibrators produces dense concrete with a minimum percentage of voids. A void ratio of 5% may reduce the concrete strength by about 30%. The curing conditions exercise an important influence on the strength of concrete. Both moisture and temperature have a direct effect on the hydration of cement. The longer the period of moist storage, the greater the strength. If the curing temperature is higher than the initial temperature of casting, the resulting 28-day strength of concrete is reached earlier than 28 days.

Age of Concrete

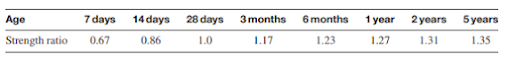

The strength of concrete increases appreciably with age, and hydration of cement continues for months. In practice, the strength of concrete is determined from cylinders or cubes tested at the age of 7 and 28 days. As a practical assumption, concrete at 28 days is 1.5 times as strong as at 7 days: The range varies between 1.3 and 1.7. The British Code of Practice [2] accepts concrete if the strength at 7 days is not less than two-thirds of the required 28-day strength. For a normal portland cement, the increase of strength with time, relative to 28-day strength, may be assumed as follows:

Loading Conditions

No comments